Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Sanitary seamless steel tubes are high-quality stainless steel tubes specifically designed for use in sanitary applications. These tubes are manufactured using a seamless process, ensuring a smooth and uniform surface without any welded joints. The seamless construction eliminates the risk of contamination and facilitates easy cleaning, making them ideal for industries such as food, beverage, pharmaceuticals, and biotechnology.

| Product Name: | Sanitary Seamless Steel Tube |

| Material: | SS304 / SS316L / 1.4301 / 1.4404 |

| Production Standards: | ASTM A270 , AS 1528.1 , EN 10357 , DIN 11850 ,ISO 2037 , JIS G3447, KS D 3585 and so on. |

| Outer Diameter: | 16mm - 2000mm ; |

| Thickness: | 0.8mm - 20 mm ; |

| Length: | 6 Meters - 18.3 Meters ; As customers' request |

| Tolerance: | According to the Standard , +/-10% Commonly ; |

| Test: | Flaring test ; Flattening test ; Bending Test ; Hydraulic Test ; Eddy Current test |

| Surface Treatment: | Mirror polishing/matt polishing |

| Certificate: | ISO9001 |

Seamless Construction with Smooth Surface Eliminates Bacteria Production: Sanitary seamless steel tubes are meticulously crafted to provide a flawless and uninterrupted surface, completely free from any welded joints. This seamless construction not only guarantees a smooth and continuous tube, but also eliminates the potential for bacteria or impurities to become trapped in weld seams.

Even Thickness and Circumference Ensures Consistent Flow: Sanitary seamless tubes offer a superior construction that guarantees uniform dimensions along the entire length of the tube. This seamless design ensures a consistent flow, minimizing the risk of turbulence or blockages. By maintaining a smooth and uninterrupted interior surface, these tubes optimize fluid dynamics and enhance operational efficiency.

Easy to Install: Sanitary seamless tubes offer the added advantage of easy installation, as they can be effortlessly welded or clamped into place. This streamlined installation process ensures a quick and straightforward setup, saving valuable time and resources.

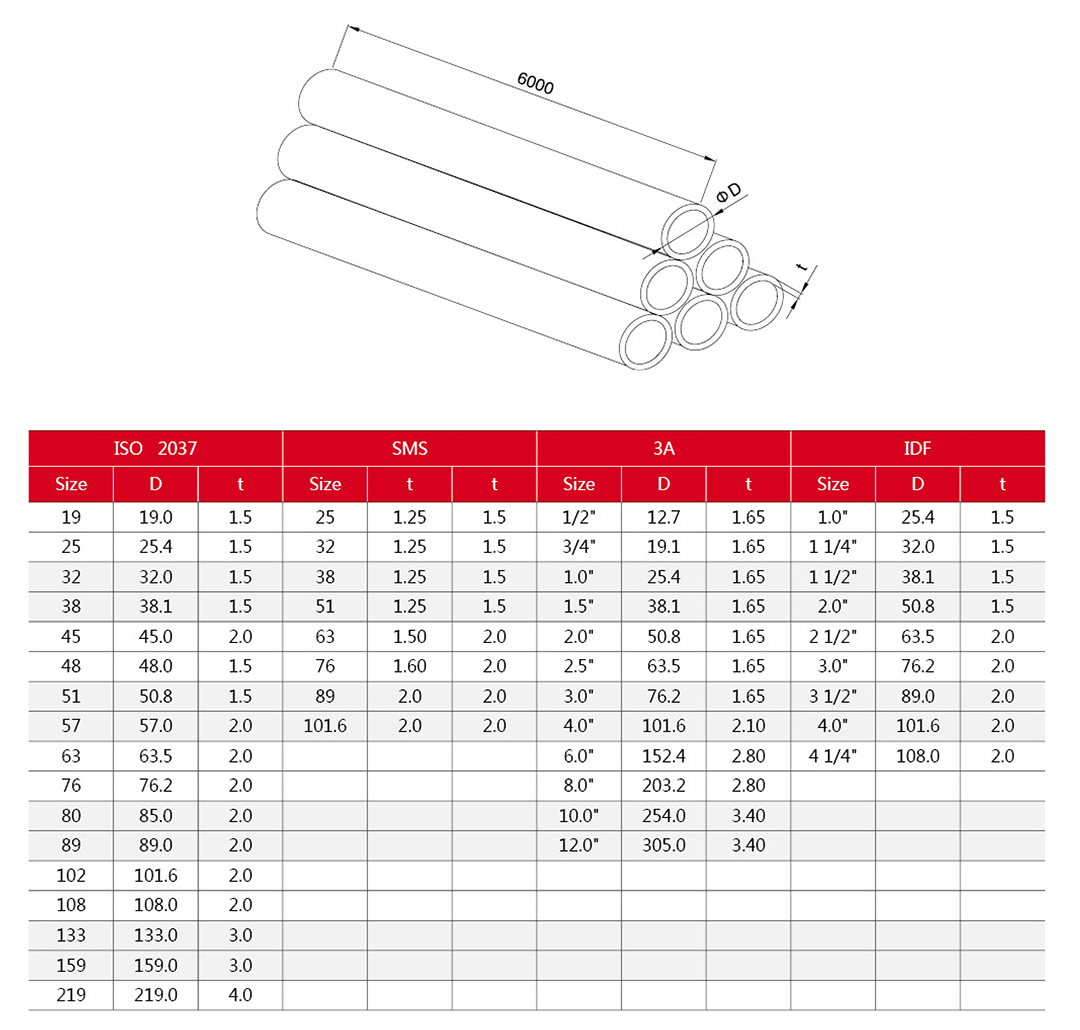

Product drawing

Superior Resistant to High Temperatures and Pressures: Sanitary seamless tubes excel in demanding applications due to their exceptional ability to withstand extreme temperatures and pressures. These tubes are engineered with high-quality materials and advanced manufacturing techniques, ensuring their durability and reliability even in the most challenging environments.

Various Sizes and Configurations to Meet Your Needs: Seamless tubes offer a wide range of options to meet diverse installation requirements. Available in various sizes and configurations, including round, square, and rectangular shapes, these tubes can be tailored to fit specific project needs. This versatility allows for seamless integration into different systems and ensures compatibility with a variety of equipment and components.