Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

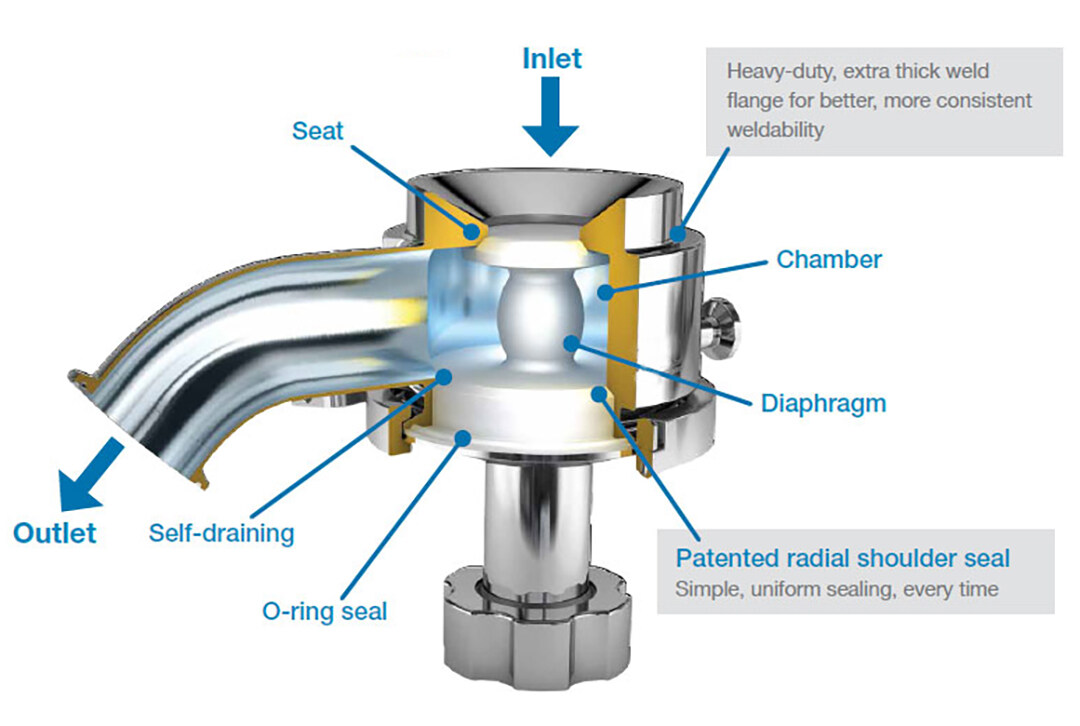

This sanitary tank flush bottom valve is specifically engineered to provide reliable and precise control over the flow of liquids, while ensuring maximum cleanliness and product integrity. With its robust construction and advanced features, it is an ideal choice for applications in industries such as food and beverage, pharmaceutical, and biotechnology.

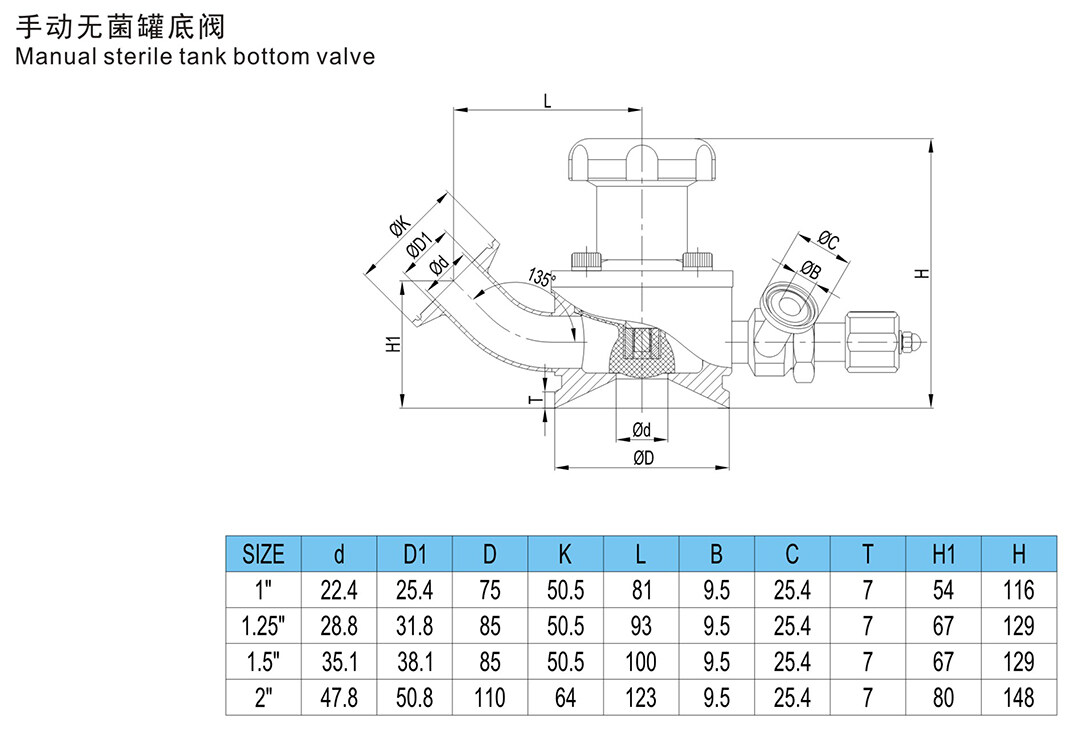

Product parameter

| Standard | SMS, 3A, DIN | |

| Material Contact Parts | SS316L(1.4404) | Provided with material inspection report |

| Material Non-contact Parts | SS304(1.4301) | |

| Size | 3/4”, 1”, 1.25”, 1.5”, 2”, DN20, DN25, DN32, DN40, DN50 | |

| Inlet Connection | Flush Bottom | |

| Outlet Connection | Butt-weld,Tri-clamp | |

| Seal Material | PTFE, the material comply with FDA21CFR117.2600 | |

| Drive Option | Manual, Pneumatic Control | |

| Pressure Range | 0~10bar(0~145psi) | |

| Working Temperature | PTFE -4 ~ 266°F(-20~ + 130℃) | |

| Sterilization Temperature | 302°F (150℃)≤30min | |

| External Surface Treatment | Ra32~64uin(0.8~1.6um) | |

| Internal Surface Treatment | Ra16~32uin(0.2~0.45um) |

Our sanitary tank flush bottom valve is meticulously crafted to meet the unique requirements of tank discharge processes. It is designed to be installed at the bottom of tanks or vessels, allowing for complete drainage and minimizing product waste. This valve is widely used in industries where maintaining hygiene and preventing contamination are critical factors in ensuring product quality and safety.

With its hygienic design and precise engineering, our sanitary tank flush bottom valve meets the stringent requirements of industries with strict sanitary standards. It is crafted from high-quality stainless steel, featuring a smooth and crevice-free interior surface. This design minimizes the risk of bacterial growth and facilitates easy cleaning and sterilization, ensuring optimal hygiene standards are met

Product drawing

Product Features

Application scenario

Product Advantages

Enhanced Product Quality: The sanitary tank flush bottom valve ensures the complete and efficient discharge of liquids, minimizing product waste and preserving product quality. It eliminates the risk of residual fluids or contaminants, ensuring the integrity and purity of the final product.

Improved Efficiency: The valve’s efficient drainage capabilities and precise flow control contribute to enhanced process efficiency. It enables faster tank emptying, reduces production time, and optimizes resource utilization.

Easy Maintenance: The valve’s design allows for easy disassembly and cleaning, minimizing downtime and facilitating routine maintenance procedures. This ensures optimal performance and extends the valve’s lifespan.