Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

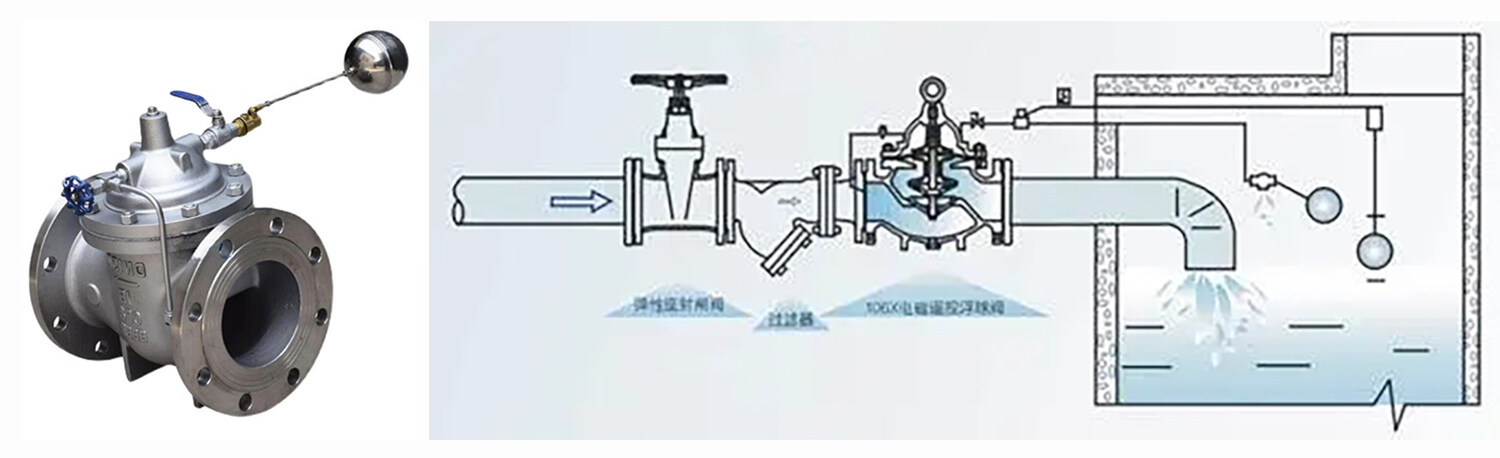

Our sanitary threaded float valve is specifically designed to meet the demanding requirements of hygienic industries. It offers precise control over fluid levels, allowing operators to maintain optimal process conditions. This valve is widely used in applications where accurate level control is critical for ensuring product quality, preventing overflows or underfills, and optimizing process efficiency.

Product parameter

| Commodity | Float Ball Valve | |

| Component | Valve Body, Valve Cap, Seal, Plug, Rod, Ball, Nut | |

| Type of Float Ball Valve | Stainless Steel Float Ball Valve | |

| Small Hole Float Ball Valve | ||

| Plastic Float Ball Valve | ||

| Design Type | Levered Type, Straight Through | |

| Material Contact Parts | SS304(1.4301),SS316 (1.4401),Brass,SS201 | Provided with material inspection report |

| Material Non-contact Parts | SS304(1.4301),SS201 | |

| Sealing Material | NBR,EPDM,Silicone,FKM. All material comply with FDA21CFR117.2600 | |

| Connection Size | DN15,DN20,DN25,DN32,DN40,DN50,DN65,DN80,DN100 | |

| Ball Size | 95mm,135mm,150mm,225mm,250mm,280mm,300mm | |

| Connection | Screw Thread, Tri-clamp,Flange | |

| Max. Pressure | 16bar (232psi) | |

| Workingl Pressure | 6bar (87psi) | |

| Design Temperature | -4 ~ +392°F (-20℃~+200 ℃) | |

| Rotation Angle | 360° | |

| Drive Mode | Hydraulic Control | |

| Flow Direction | Single One-way | |

| Media | Water | |

| Customized Support | OEM,OED | |

The sanitary threaded float valve is a crucial component in hygienic processes, providing reliable and efficient control of fluid levels. This valve utilizes a float mechanism to regulate the flow of liquids or gases, ensuring precise level control. With its hygienic design, advanced features, and dependable performance, it is the ideal choice for industries such as food and beverage, pharmaceutical, and biotechnology that require accurate level control for process optimization and quality assurance.

Product drawing

|

S/N |

Item |

Material |

|

|

1 |

Valve Body |

SS304/SS316/SS201/Brass |

|

|

2 |

Valve cap |

SS304/SS316/SS201/Brass |

|

|

3 |

Seal |

NBR,EPDM,Silicone,FKM |

|

|

4 |

Plug |

SS304/SS316/SS201/Brass |

|

|

5 |

Stem |

SS304/SS316/SS201/Brass |

|

|

6 |

Ball |

SS304/SS316/SS201/Brass |

|

|

7 |

Nuts |

SS304/SS316/SS201/Brass |

|

| Size | Valve Body Length | Rod Length | Thread Length | Float Ball Length | Net Weight | Gross Weight | Technical Parameter | |

| DN15 | G1/2" | 65mm | 150mm | 13mm | 100mm | 260g | 330g |

-4 ~ +392°F (-20℃~+200 ℃) 16bar (232psi) |

| DN15 | G1/2" | 47mm | 285mm | 17mm | 115mm | 260g | 330g | |

| DN15 | G1/2" | 70mm | 220mm | 14mm | 110mm | 285g | 355g | |

| DN20 | G3/4" | 65mm | 150m | 13mm | 100mm | 285g | 350g | |

| DN20 | G3/4" | 54mm | 365mm | 19mm | 135mm | 285g | 350g | |

| DN25 | G1" | 89mm | 215mm | 19mm | 135mm | 560g | 670g | |

| DN32 | G1-1/4" | 89mm | 230mm | 22mm | 150mm | 660g | 750g | |

| DN40 | G1-1/2" | 110mm | 220mm | 27mm | 220mm | 1700g | 6kg | |

| DN50 | G2 | 120mm | 200mm | 30mm | 250mm | 2000g | 6kg | |

| DN65 | G2-1/2" | 150mm | 280mm | 31mm | 300mm | 3500g | 9kg | |

| DN80 | G3" | 170mm | 240mm | 34mm | 380mm | 5000g | 10kg | |

| DN100 | G4" | 195mm | 240mm | 40mm | 380mm | 7000g | 12kg | |

Product Features

Application scenario

Product Advantages

1.Accurate Level Control: The sanitary threaded float valve ensures precise level control, allowing operators to maintain optimal fluid levels in the process. This prevents overflows or underfills, contributing to efficient and reliable process performance.

2.Quality Assurance: With accurate level control, the valve helps in ensuring consistent product quality. It prevents variations due to incorrect fluid levels, contributing to reliable and high-quality products.

3.Compliance with Hygiene Standards: The float valve’s hygienic design and compatibility with cleaning and sterilization processes ensure compliance with stringent hygiene standards. It is suitable for use in industries with strict sanitary requirements, such as food and beverage, pharmaceutical, and biotechnology.

Applications

Biotechnology Industry: The sanitary threaded float valve is extensively used in biotechnology applications, such as bioreactors, fermentation tanks, and cell culture vessels. It enables precise control of liquid levels, ensuring optimal conditions for cell growth, nutrient supply, and product yield.

Brewing and Distilling Industry: The sanitary threaded float valve is essential in brewing and distilling processes, where precise level control is crucial for maintaining consistent product quality and preventing overflows.