Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

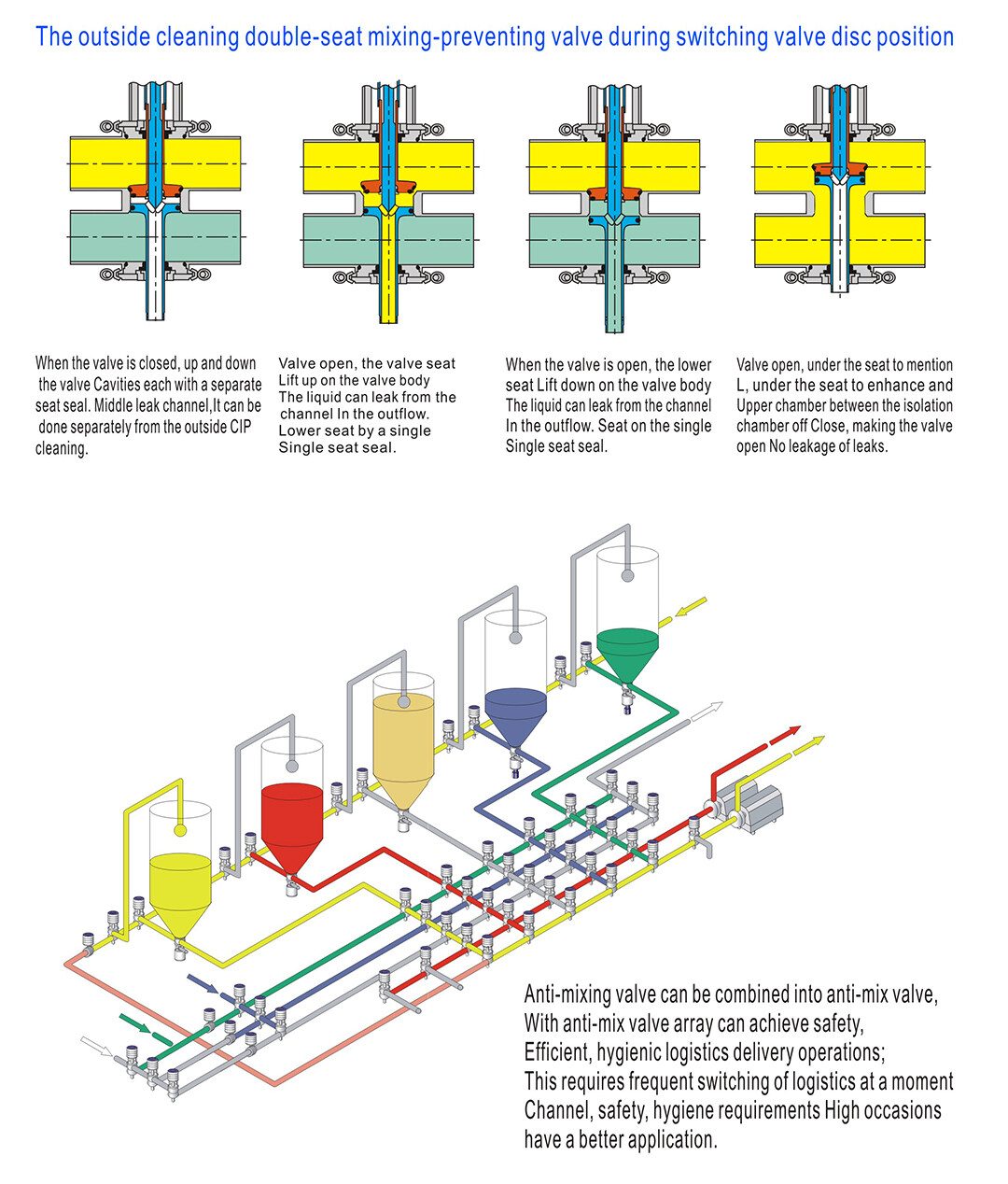

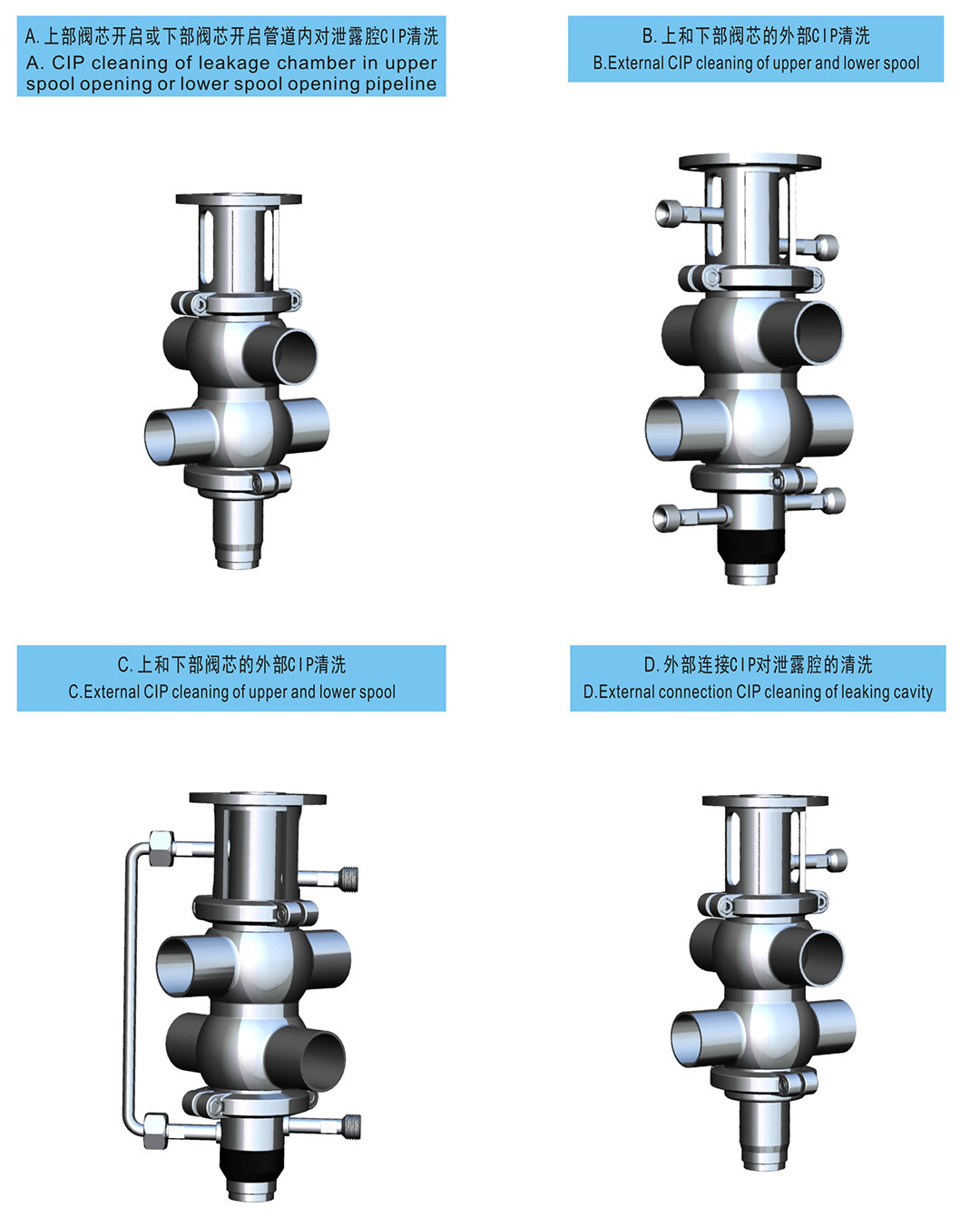

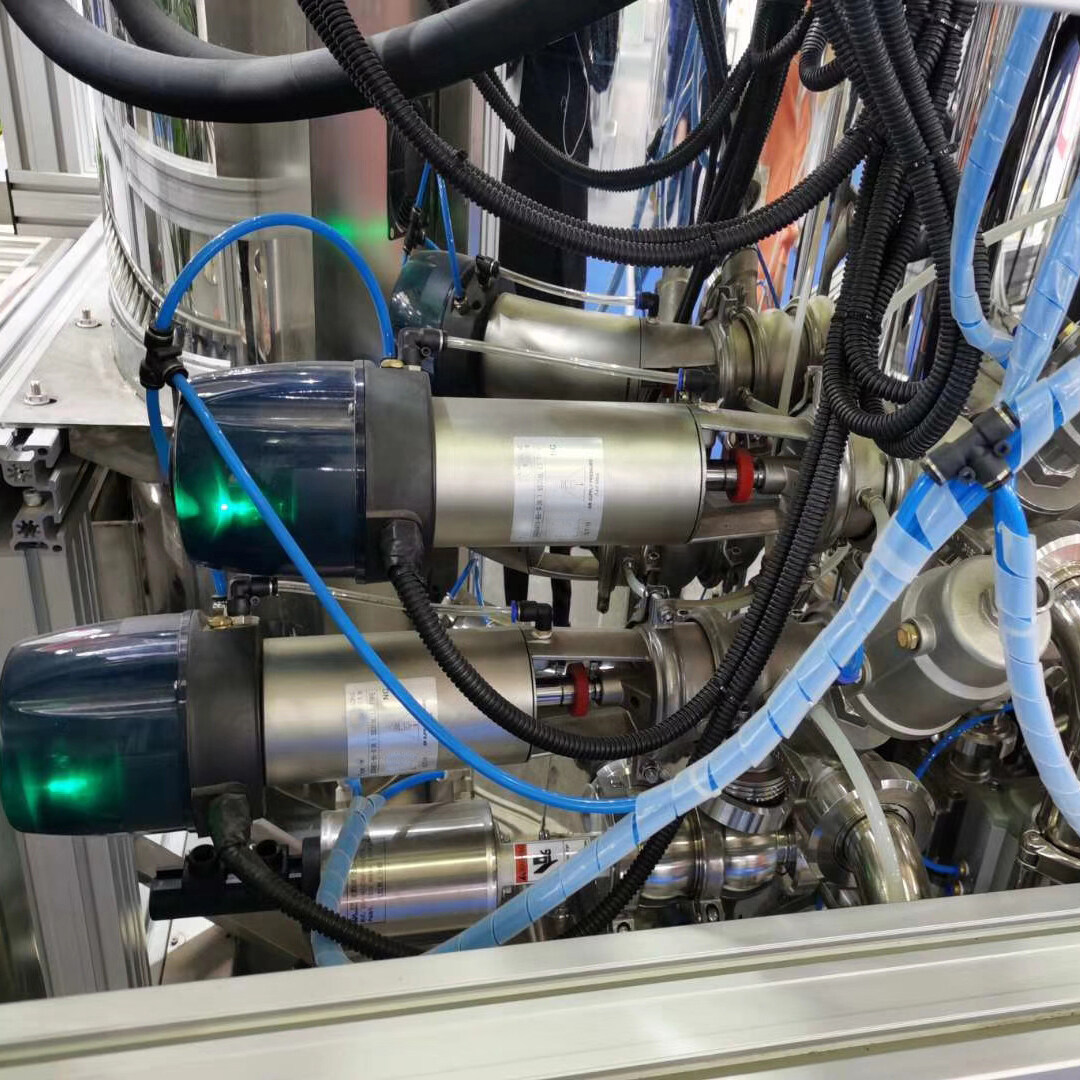

The sanitary mixproof valve with C-Top is an advanced solution designed to provide efficient and reliable separation of different media in hygienic processes. This valve offers a unique double-seat design, allowing for simultaneous control of two separate fluids without the risk of cross-contamination.With its superior performance and hygienic construction, it is an ideal choice for applications requiring strict product separation and maximum hygiene.

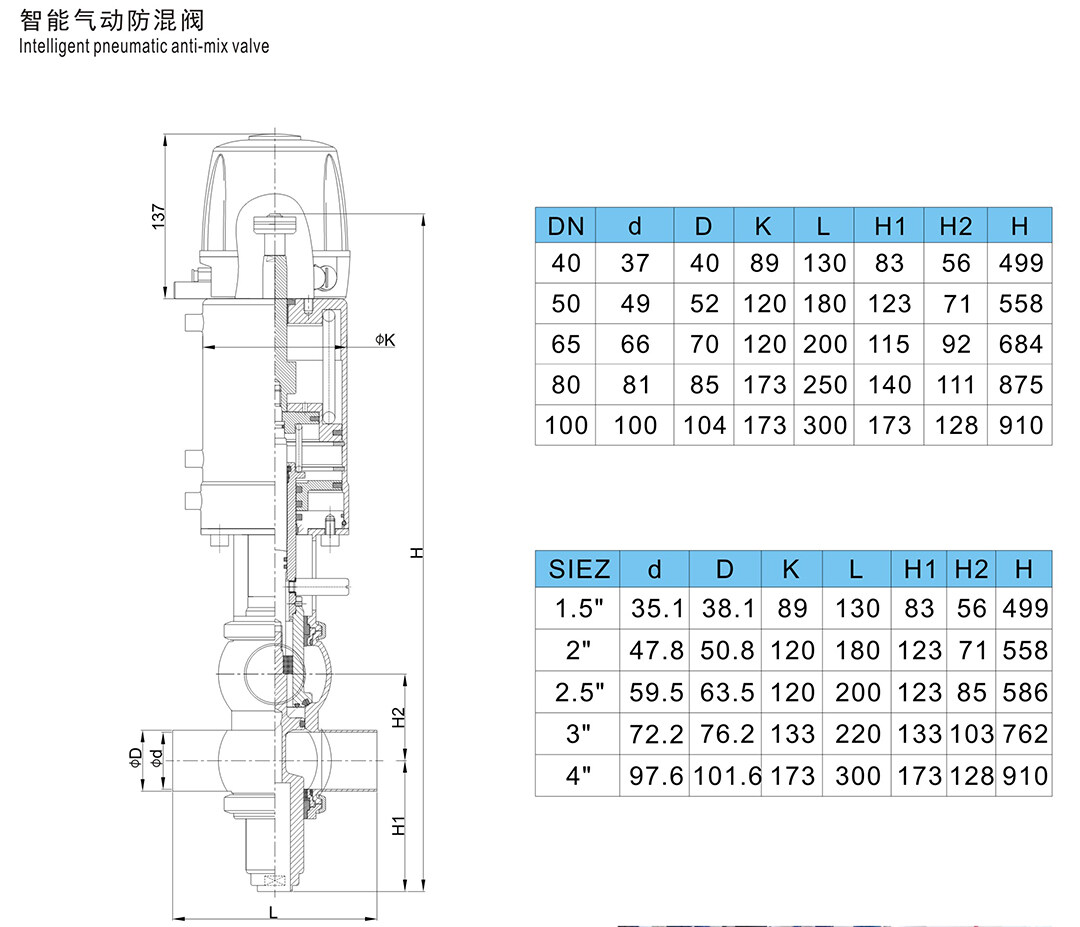

Product parameter

| Standard | SMS,DIN,3A | |

| Material Contact Parts | SS304/SS316L(1.4301/1.4404) | Provided with material inspection report |

| Material Non-contact Parts | SS304(1.4301) | |

| Size | 1.5“”-4”, DN40-DN100 | |

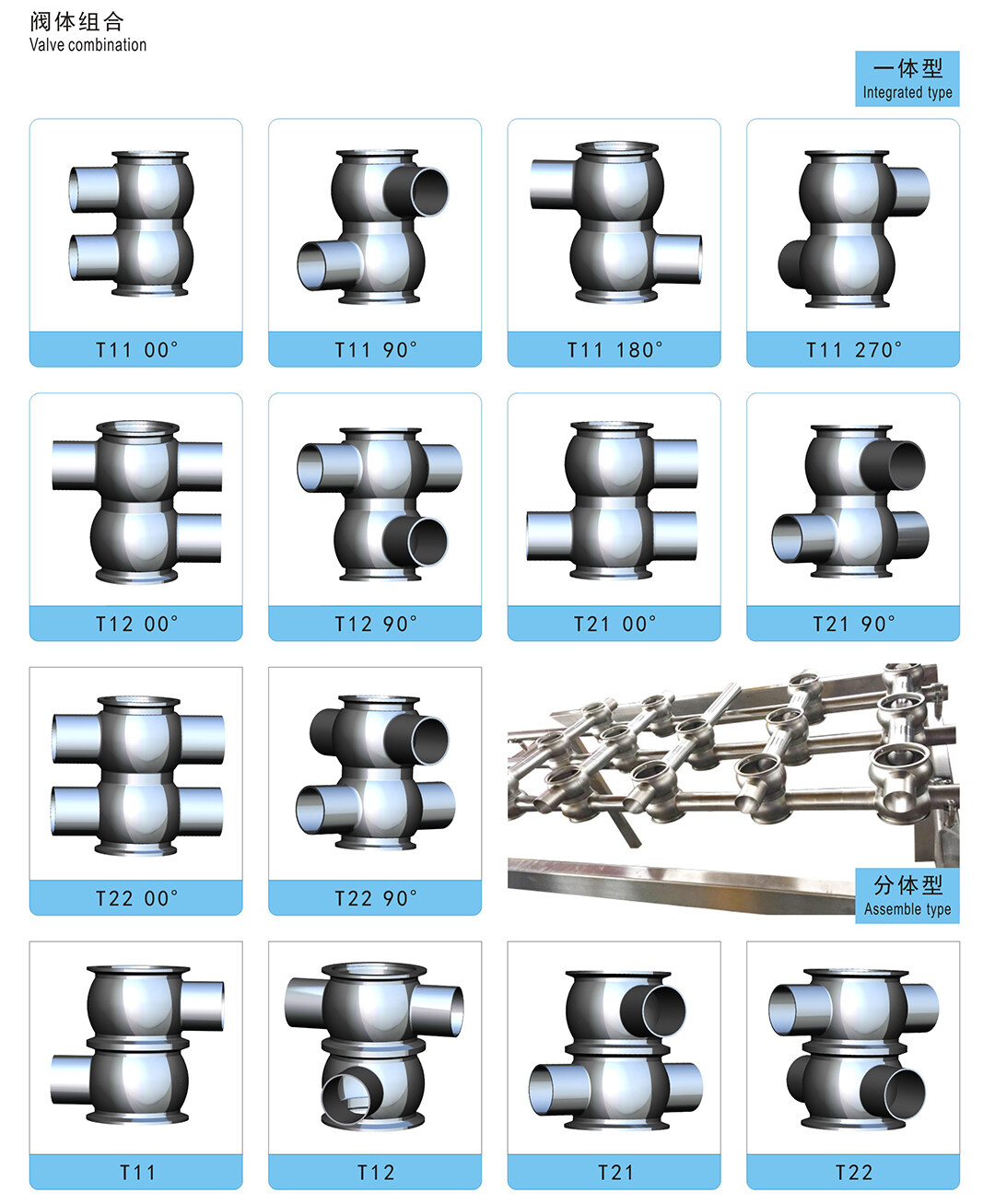

| Integrated Body Combination |

T11 00°,T11 90°,T11 180°,T11 270° T12 00°,T12 90° T21 00°,T21 90° T22 00°,T22 90° |

|

| Assemble Body Combinatio | T11, T12, T21, T22 | |

| Connection | Butt-weld,Tri-clamp,Male Thread,Female-Male Threaded,Union,Weld-Thread,Flange | |

| Seal Material | Silicone,EPDM,FKM,Buna. All seals material comply with FDA21CFR117.2600 | |

| Power Option | Position Sensor, C-top Controller, C-top Controller (AS-I) | |

| Working Pressure | ≤10bar(145psi) | |

| Supply Pressure for Air Actuator | 6~8(87psi~116psi) | |

| External Surface Treatment | Ra32~64uin(0.8~1.6um) | |

| Internal Surface Treatment | Ra16~32uin(0.4~0.8um) | |

Our sanitary mixproof valve with C-top is engineered with precision to meet the stringent requirements of hygienic industries. It is specifically designed to ensure the complete isolation of incompatible fluids, preventing any possibility of mixing or contamination. This valve is widely used in industries such as food and beverage, dairy, pharmaceutical, and cosmetics, where maintaining product integrity and hygiene is of utmost importance.

Product drawing

Product Features

Application scenario

Product Advantages

1.Enhanced Product Safety: The double-seat design of the Sanitary mixproof valve goes above and beyond in ensuring the utmost product safety. By providing complete separation of incompatible fluids, it eliminates any possibility of cross-contamination. This feature is particularly crucial in industries where maintaining product integrity is paramount, such as the food and beverage, dairy, pharmaceutical, and cosmetics sectors.

2.Cost Savings: By preventing product loss through its reliable double-seat design, it minimizes waste and maximizes your operational efficiency. Additionally, the valve’s efficient cleaning capabilities and easy maintenance procedures reduce downtime, allowing for more productive uptime.

3.Compliance with Hygiene Standards: The sanitary mixproof valve is purposefully designed to meet and exceed these stringent regulations. Its hygienic construction, crafted from high-quality stainless steel, ensures a smooth and crevice-free interior surface. This design minimizes the risk of bacterial growth and facilitates thorough cleaning and sterilization.